As a consulting firm that has been in business for more than 15 years, EOS promotes activities that are recognized by third parties. Therefore activities that are carried out to date have proven the concern and performance of EOS Consulting Services in dealing with various environmental issues.

As a consulting organization that has long handled environmental issues within the region of Indonesia, EOS pays close attention to its core values. The current EOS’ activities are a reflection of interpreting its Vision and Mission that is reflected in EOS’ implementation day to day basis.

The services being delivered by EOS are part of the product that needs to use internationally-recognized standards that are demanded by clients.

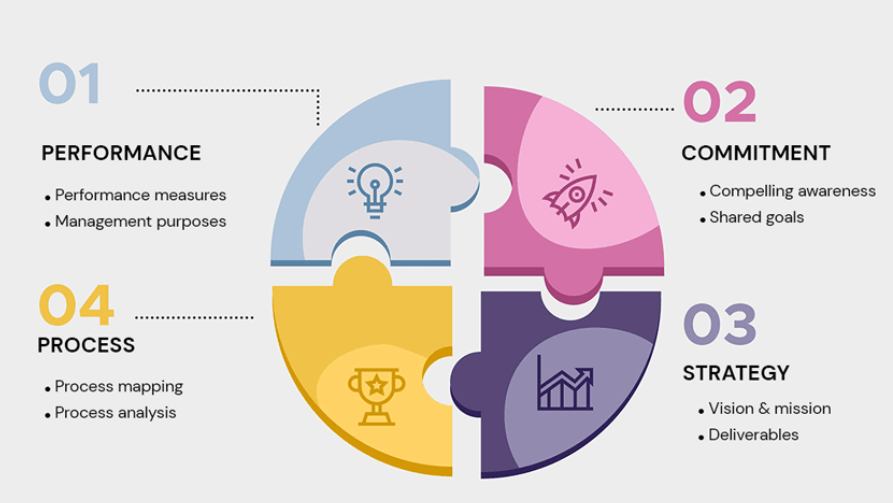

One of the core EOS’ services is relevant to Quality Management, Quality management systems are often used to determine company policies and quality objectives. In addition, the quality management system is implemented as a business indicator in generating profits.

Consultants provide a useful distance from business challenges; they are not emotionally invested in operations in the same way that business owners are and they can more easily identify and address challenges, whether the issue is implementing new technology or mechanism.

Quality (quality) in the ISO 9000 framework is defined as “the overall features and characteristics of a product or service that affect the ability of the product to satisfy certain needs”. This means that the consultation business must be able to identify the characteristics of the product related to quality and then create a basic benchmark and develop the mechanism to control the activities of the business itself.

Quality management is a series of actions used to ensure the quality of goods or services produced. This is very important, considering that both companies and businesses want the quality of their products to be consistent.

In this case, EOS has considered quality management as an assurance to consumers about the production process and services.

One of the series of quality management system standards that is often applied is ISO 9001. More than 187 countries have used this standard in 2017. Now, the number of users is increasing because ISO 9001, especially the ISO 9001 series, has helped companies achieve their vision and mission.

Following are principles of ISO 9001-2015 being implemented by EOS

- The first principle: Customer Focus

By providing needs beyond consumer expectations. It aims to achieve customer satisfaction. - The second principle: Leadership

Every leader in the company has responsibility for the targets set by the company. To achieve the target, must do empowerment well. - The third principle is: Involvement of Others

Providing customer satisfaction will be more easily achieved if supported by an expert. All levels in the company are well-empowered and engaged. - The fourth principle: Business Process Approach

The quality management system is basically based on pure processes that exist in the company by involving all related parties. - Fifth principle: Continuous Improvement

Companies that survive in the competitive world of industry are companies that focus on making improvements. - Therefore Continuous Improvement is an activity carried out in an ongoing effort to improve and develop a program through evaluation activities that will eventually produce solutions.

Continuous improvement will be developed through efforts that are made through evaluation activity aiming to get the best solution for existing problems for further improvement.

This activity can not only be done in a short period of time, such as one year. However, Continuous Improvement can be done in the long term and is sustainable.

Organizations that focus on continuous improvement become increasingly competitive and are able to maintain an edge over competitors. Continuous improvement of businesses ensures that processes, methods, and practices are accurate, effective, and efficient.

Continuous improvement is done by examining and improving business processes to eliminate bottlenecks by using the best software option and management methodology. CPI on the other hand focuses only on processes to evaluate if they are meeting the company goals. Making incremental changes that provide long-term business benefits is the main aim of CPI. [https://www.cflowapps.com/continuous-process-improvement]

7. The sixth principle: Factual Approach in Decision Making

Namely by making decisions based on existing data and facts.

8. Seventh Principle: Mutually Beneficial Supplier Relations

Managing good relationships between parties in the company, for example, suppliers, employees, business partners, and others will maintain the company’s success and be able to compete.